Page 13 - TURNING CATALOG p635-848

P. 13

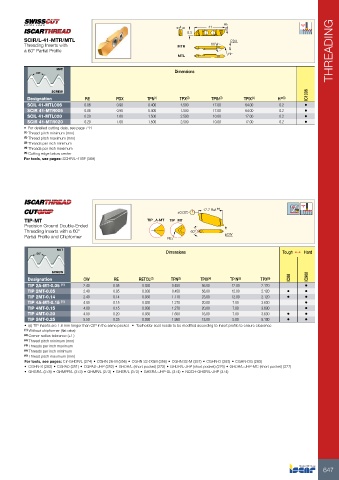

SCIR/L-41-MTR/MTL 4 41 HF IC1008

Threading Inserts with 8.5

a 60° Partial Profile 60° PDX THREADING

MTR RE

MTL

NUT

60° Dimensions

SCREW

Designation RE PDX TPN(1) TPX(2) TPIN(3) TPIX(4) HF(5)

SCIL 41-MTL006 0.06 0.90 0.400 1.500 17.00 64.00 0.2 •

SCIR 41-MTR006 0.06 0.90 0.400 1.500 17.00 64.00 0.2 •

0.20 1.60 1.500 2.500 10.00 17.00 0.2 •

SCIL 41-MTL020 0.20 1.60 1.500 2.500 10.00 17.00 0.2 •

SCIR 41-MTR020

• For detailed cutting data, see page 711

(1) Thread pitch minimum (mm)

(2) Thread pitch maximum (mm)

(3) Threads per inch minimum

(4) Threads per inch maximum

(5) Cutting edge below center

For tools, see pages: SCHR/L-41BF (369)

±0.025 17.7 Ref.(a)

TIP _A-MT TIP _MT

TIP-MT

Precision Ground Double-Ended 60° CW

Threading Inserts with a 60° RE

Partial Profile and Chipformer

Dimensions Tough 1 Hard

NUT

60°

SCREW IC08

IC908

Designation CW RE RETOL(2) TPN(3) TPIX(4) TPIN(5) TPX(6)

•

TIP 2A-MT-0.05 (1) 2.40 0.05 0.030 0.450 56.00 12.00 2.120 •

2.120 • •

TIP 2MT-0.05 2.40 0.05 0.030 0.450 56.00 12.00 2.120 • •

•

TIP 2MT-0.14 2.40 0.14 0.030 1.110 23.00 12.00 •

•

TIP 4A-MT-0.15 (1) 4.00 0.15 0.030 1.270 20.00 7.00 3.630

TIP 4MT-0.15 4.00 0.15 0.030 1.270 20.00 7.00 3.630

3.630 •

TIP 4MT-0.20 4.00 0.20 0.030 1.600 16.00 7.00 5.100 •

TIP 5MT-0.25

5.50 0.25 0.030 1.950 13.00 5.00

• (a) TIP inserts are 1.6 mm longer than GIP in the same pocket • Toolholder seat needs to be modified according to insert profile to ensure clearance

(1) Without chipformer (flat rake)

(2) Corner radius tolerance (+/-)

(3) Thread pitch minimum (mm)

(4) Threads per inch maximum

(5) Threads per inch minimum

(6) Thread pitch maximum (mm)

For tools, see pages: C#-GHDR/L (274) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357) • CGHN-D (283) • CGHN-DG (283)

• CGHN-S (282) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276) • GHDR/L-JHP-MC (short pocket) (277)

• GHGR/L (278) • GHMPR/L (273) • GHMR/L (273) • GHSR/L (373) • GHSR/L-JHP-SL (374) • NQCH-GHSR/L-JHP (374)

647