Page 5 - TURNING CATALOG p459-634

P. 5

PARTING SELECTION GUIDE PARTING

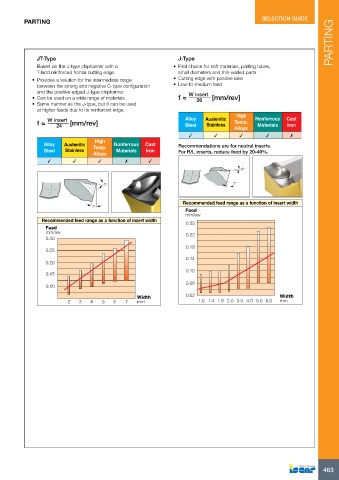

JT-Type J-Type

Based on the J-type chipformer with a • First choice for soft materials, parting tubes,

T-land reinforced frontal cutting edge. small diameters and thin-walled parts

• Provides a solution for the intermediate range • Cutting edge with positive rake

between the strong and negative C-type configuration • Low-to-medium feed

and the positive edged J-type chipformer.

f ≈ W insert [mm/rev]

• Can be used on a wide range of materials. 26

• Same manner as the J-type, but it can be used

High

at higher feeds due to its reinforced edge. Temp.

Alloys

f ≈ W insert [mm/rev] Alloy Austenitic Nonferrous Cast

24 Steel Stainless 3 Materials Iron

3 3 37

Alloy Austenitic High Nonferrous Cast Recommendations are for neutral inserts.

Steel Stainless Temp. Materials Iron For R/L inserts, reduce feed by 20-40%.

Alloys

3 3 7 3

3

5° 4°

7°

7° Recommended feed range as a function of insert width

Feed

Recommended feed range as a function of insert width mm/rev

Feed 0.25

mm/rev 0.22

0.30

0.25 0.18

0.14

0.20

0.15 0.10

0.10 0.06

Width

0.02 Width

2 3 4 5 6 7 mm 1.0 1.4 1.6 2.0 3.0 4.0 5.0 6.0 mm

463