Page 4 - TURNING CATALOG p459-634

P. 4

PARTING PARTING SELECTION GUIDE

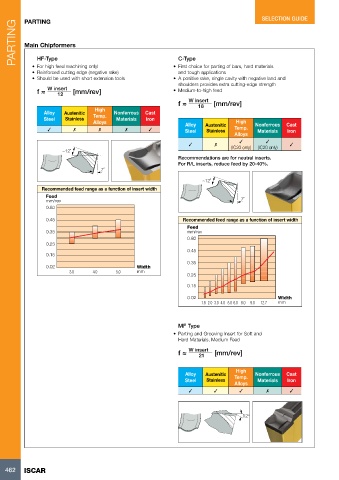

Main Chipformers

HF-Type C-Type

• For high feed machining only! • First choice for parting of bars, hard materials

• Reinforced cutting edge (negative rake) and tough applications

• Should be used with short extension tools

• A positive rake, single cavity with negative land and

f ≈ W insert [mm/rev] shoulders provides extra cutting-edge strength

12

• Medium-to-high feed

f ≈ W insert [mm/rev]

18

High

Alloy Austenitic Temp. Nonferrous Cast Alloy Austenitic High Nonferrous Cast

Steel Stainless Alloys Materials Iron Steel Stainless Temp. Materials Iron

Alloys

3 7 7 7 3 3 7 3 3

3 (IC20 only)

~12˚ (IC20 only)

7˚ Recommendations are for neutral inserts.

For R/L inserts, reduce feed by 20-40%.

Recommended feed range as a function of insert width

Feed ~12˚

mm/rev

0.80 7˚

0.45

0.35 Recommended feed range as a function of insert width

0.25 Feed

0.15 mm/rev

0.02 Width 0.80

3.0 4.0 5.0 mm

0.45

0.35

0.25

0.15

0.02 Width

1.6 2.0 3.0 4.0 5.0 6.0 8.0 9.0 12.7 mm

MF Type

• Parting and Grooving Insert for Soft and

Hard Materials, Medium Feed

f ≈ W insert [mm/rev]

21

Alloy Austenitic High Nonferrous Cast

Steel Stainless Temp. Materials Iron

Alloys

3 3 73

3

12°

462 ISCAR