Page 16 - Flash Solid Catalog

P. 16

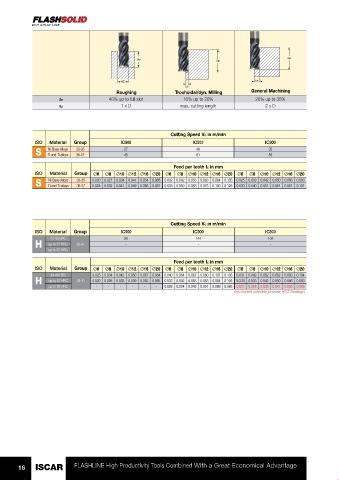

ap ap ap

AE AE

Roughing AE General Machining

Trochoidal/dyn. Milling

ae 40% up to full slot 10% up to 20% 20% up to 35%

ap 1xD max. cutting length 2xD

ISO Material Group IC900 Cutting Speed Vc in m/min IC900

S Ni-Base Alloys 33-35 27 IC900 35

Ti and Ti-alloys 36-37 45 49 59

81

Feed per tooth fz in mm

ISO Material Group Ø6 Ø8 Ø10 Ø12 Ø16 Ø20 Ø6 Ø8 Ø10 Ø12 Ø16 Ø20 Ø6 Ø8 Ø10 Ø12 Ø16 Ø20

S Ni-Base Alloys 33-35 0.020 0.027 0.034 0.041 0.054 0.068 0.032 0.042 0.053 0.063 0.084 0.105 0.025 0.033 0.042 0.050 0.066 0.083

Ti and Ti-alloys 36-37 0.024 0.032 0.041 0.049 0.065 0.081 0.038 0.050 0.063 0.075 0.100 0.125 0.030 0.040 0.051 0.061 0.081 0.101

ISO Material Group IC900 Cutting Speed Vc in m/min IC900

H 44-48 HRC 38-41 80 IC900 104

up to 57 HRC - 144 -

up to 62 HRC - - -

-

Feed per tooth fz in mm

ISO Material Group Ø6 Ø8 Ø10 Ø12 Ø16 Ø20 Ø6 Ø8 Ø10 Ø12 Ø16 Ø20 Ø6 Ø8 Ø10 Ø12 Ø16 Ø20

H 44-48 HRC 38-41 0.025 0.034 0.042 0.050 0.067 0.084 0.040 0.054 0.067 0.080 0.107 0.135 0.031 0.042 0.052 0.062 0.083 0.104

up to 57 HRC 0.020 0.026 0.033 0.039 0.052 0.065 0.032 0.042 0.053 0.063 0.084 0.105 0.0.25 0.033 0.042 0.050 0.066 0.083

up to 62 HRC 0.026 0.034 0.043 0.051 0.068 0.085 0.021 0.028 0.035 0.041 0.055 0.069

- - - - - -

only limited possible (choose HSC Strategy)

16 ISCAR FLASHLINE High Productivity Tools Combined With a Great E conomical Advantage