Page 12 - machining_titanium_05_2019

P. 12

MILLING TITANIUM Some facts about carbide grades

A carbide grade is the combination of three elements: a tungsten carbide substrate, which is

produced by powder-metallurgy technology, a wear-resistant coating and a post-coating treatment,

while only although only the substrate is essential. In some cases a specific tungsten carbide

may act as an uncoated grades; while in other cases it will be a substrate of a coated grade.

SUMO TEC is a special post coating treatment of indexable inserts, which provides substantially

improved tool life and better reliability.

It has the effect of making the rake face of an insert even and uniform, minimizing inner stresses,

cracks and droplets in coating that leads to smooth chip flow and extended tool life.

ISCAR PVD coated grades IC840 and IC882 have a bronze chocolate color. The periphery

of inserts, which are made from SUMO TEC CVD coated grade IC 5820, is also a brown

shade. Development of these “sun tan” grades was directed exactly towards milling ISO S

(titanium and heat-resistant alloys) and ISO M (austenitic and austenitic/ferritic stainless steel)

materials. ISCAR believes that the above “sunbathed” cemented carbides (Fig. 4) will bring

a real premium-class cutting “assorted chocolate” to the manufacturer of titanium parts.

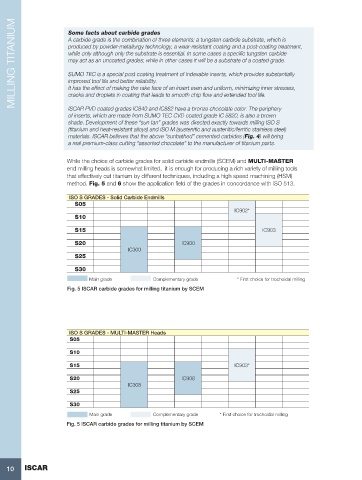

While the choice of carbide grades for solid carbide endmills (SCEM) and MULTI-MASTER

end milling heads is somewhat limited, it is enough for producing a rich variety of milling tools

that effectively cut titanium by different techniques, including a high speed machining (HSM)

method. Fig. 5 and 6 show the application field of the grades in concordance with ISO 513.

ISO S GRADES - Solid Carbide Endmills

S05

IC902*

S10

S15 IC903

S20 IC900

IC300

S25

S30

Main grade Complementary grade * First choice for trochoidal milling

Fig. 5 ISCAR carbide grades for milling titanium by SCEM

ISO S GRADES - MULTI-MASTER Heads

S05

S10

S15 IC903*

S20 IC908

IC308

S25

S30

Main grade Complementary grade * First choice for trochoidal milling

Fig. 5 ISCAR carbide grades for milling titanium by SCEM

10 ISCAR